Gas turbines

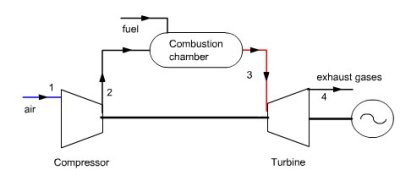

a compressor , usually centrifugal or axial, which is used to compress the ambient air at a pressure between 10 and 30 bar in modern machines;

a combustion chamber , in which fuel is injected under pressure, combusted with air previously compressed (the latter in large excess in order to limit the exhaust gases temperature at the turbine inlet);

a turbine , usually axial, in which are expanded the high temperature gases exiting the combustion chamber.A significant proportion (60-70%) of the work recovered on the shaft of the turbine is used to drive the compressor.

In this form the gas turbine engine is a continuous stream internal combustion engine. Note that the gas turbine term comes from the working fluid state, which remains gaseous, and not the fuel used, which can be both gaseous and liquid (gas turbines typically use natural gas or light petroleum distillates). There are also closed cycle gas turbines, used for special applications, including nuclear. Of course, then it is an external combustion engine.

To achieve compression ratios r of 20 or 30, the compressor is multistage, with sometimes intermediate cooling to reduce the work consumed. Axial rotors are made of a stack of discs, either mounted on a central shaft, or drum assembled on their periphery. The materials used are aluminum or titanium alloys for the first stages and steel alloys and refractory alloys for last stages that can withstand temperatures up to 500 °C.

The combustion chamber is normally constructed of refractory alloy.

In open cycle gas turbine, the main technological constraints are at the first stages of the expansion turbine, through which flow the exhaust gas at high temperature

The parts most at risk are especially rotor blades, which are very difficult to cool and in addition particularly sensitive to abrasion. It is therefore important to use a very clean fuel (no particles and chemicals that may form acids), and limit the temperature depending on the mechanical characteristics of the blades. The materials used for turbine blades are refractory alloys based on nickel or cobalt, and manufacturers intend to make use of ceramics in the future.

As the cycle efficiency is itself an increasing function of temperature, major technological developments have been devoted to the fabrication, first of efficient cooling systems of the blades, and second of materials resistant at high temperatures. For half a century, there has been a gradual increase (about 20 °C per year) of the turbine inlet temperature, now reaching 1300 to 1500 °C.

Advanced gas turbine cycles

Many variants of the basic cycle of the gas turbine shown above have been proposed. A number are the subject of thematic pages to which you can refer:

Book references

An excerpt of the textbook chapter is freely downloadable with the agreement of CRC Press

Available Diapason sessions

Diapason sessions dealing with open cycle gas turbines are given in the table below. Session S20En is specifically dedicated to technology, while others allow you to build in Thermoptim models of various gas turbines;

in session S21En, it is assumed that the machine working fluid is air, it itself assumed to be a perfect gas, which allows you to compare the model results with those of a purely analytical model;

session S22En complements the previous, the intake air being considered a mixture of N2, O2 and Ar. Combustion is then considered;

session S23 allows for building the exergy balance of the machine and to explore a regeneration variant;

session S24 allows you to directly build a model of gas turbine with combustion. In a sense, it summarizes sessions S21 and S22;

session S20En_aero presents turbojets, which are simple variants of gas turbines.

n° | content | steps | soundtrack duration |

|---|---|---|---|

S20 | Technologie des turbines à gaz (TAG) | 30 | 18 mn |

S21En | 29 | 12 mn 35 s | |

S22En | 5 | 2 mn 30 s | |

S23En | 10 | 5 mn 50 s | |

S24En | 17 | 6 mn 30 s | |

S20_aero | Turbomoteurs et moteurs-fusée | 27 | 16 mn |