Supercritical steam cycles

The optimum technical and economic capacity of flame Rankine steam cycles until recent years matched with boiler conditions of about 560 °C and 165 bar, leading, with a reheat and without extraction, to a thermodynamic efficiency close to 40%.

To significantly increase the efficiency, it is possible to use so-called supercritical cycles in which water pressure exceeds the critical pressure of 221.2 bar.

The result is obviously much higher stress for boiler tubes. Progress on the creep tube resistance can provide technological solutions unthinkable a short time ago.

For example, the pipe thickness needed to withstand a pressure of 225 bar and a temperature of 600 °C changed from 250 mm with steel P22 at 2.25% Cr, to 93 mm with P91 steel with 9% Cr, and 68 mm with steel HCM12A at 12% Cr (Jayet-Gendrot et al, 1999).

Another constraint faced by supercritical boilers is the following: due to the absence of vaporizer, you cannot cool the furnace by pipe screens traversed by boiling water with very high heat transfer coefficients. This is why a different technology is used, without drum separator, in so-called mono-tubular boilers (improperly because in reality the layers of tubes are arranged in parallel), or in English “once-through” to indicate the absence of recirculation. These tubes are fluted with internal and external fi ns, mounted in spiral bundles.

Supercritical cycles are not new (40% of former Soviet Union plants are supercritical, as well as more than 150 plants in the U.S.). The recent trend is to seek out increasingly high boiler conditions, and two reheats.

For example, the project High Performance Power System (HIPPS) of the U.S. Department of Energy studies cycles up to a pressure of 415 bar and a temperature of 700 ° C, while the current achievements do not exceed 325 bar and 600 ° C.

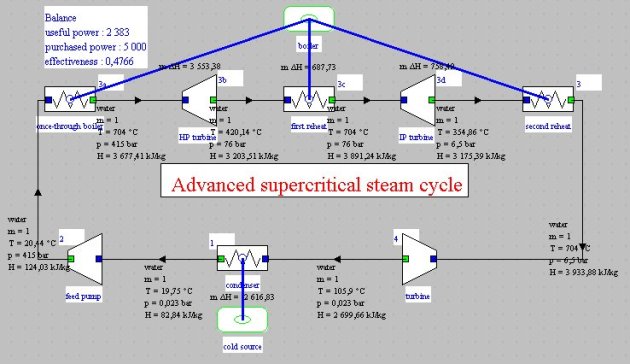

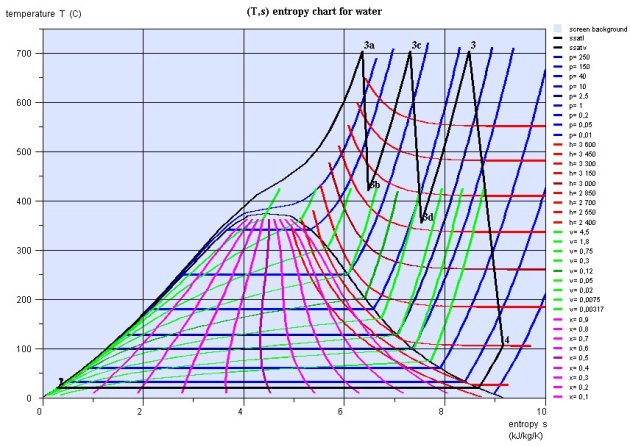

To fix ideas, we modeled in Thermoptim such an advanced supercritical steam cycle. The efficiency reaches 47.7% (against 40% for a conventional subcritical cycle). Figures below show the cycle synoptic view, and its plot in a (T, s) entropy chart.

In this example, we have simplified things by keeping an expansion isentropic efficiency of 0.85 for the different turbines. As the expansion takes entirely place in the dry zone, higher values could have legitimately been taken.

Thus, this technology provides efficiency gains between 6 and 10% depending on the steam pressure and temperature conditions, for a cost increased by 3-5%. As the addition of supercritical boilers offers more flexibility at the operational level than conventional drum boilers, their use is spreading more and more.

Project Thermie 700 involving many EU manufacturers and utilities aims to achieve LHV efficiencies of 50%.

Exercises and personal activities

An exercise on an advanced supercritical cycle is proposed. Its correction will provide the Thermoptim files allowing you to model the cycle presented above

References

S. JAYET-GENDROT, F. ARNOLDI, P. BILLARD, C. DORIER, Y. DUTHEILLET, L. LELAIT, D. RENAUD, Des matériaux innovants pour un sujet brûlant, Revue Epures, DRD EDF 1999, Paris.