Humid air gas turbine

HUMID AIR GAS TURBINE

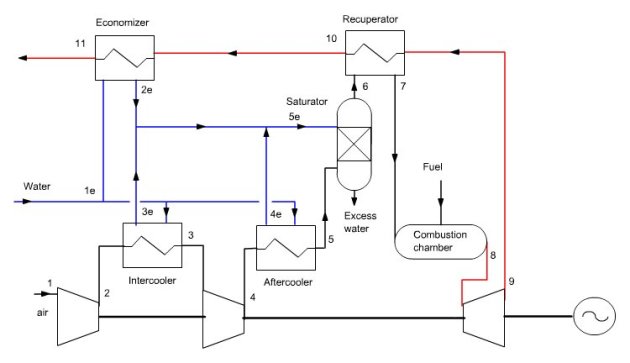

The humid air gas turbine cycle (HAT) is as shown in Figure below. It uses as working fluid system “water-air”, which can significantly improve the capacity and efficiency compared to the simple gas turbine cycle.

The intake air is compressed (1–4) at about 25 bar with intercooling and post-compression cooling (4–5), to reduce work involved while recovering heat to preheat water. Air is then introduced into a saturator which it leaves saturated with water.

The humid air is preheated in a recuperator (6–7) by exchange with the expanded fumes (9–10), then headed to the combustion chamber, where it serves as an oxidizer to a fuel. Burnt gases are expanded in the turbine (8–9), then cooled in the recuperator prior to preheat water in the economizer before entering the saturator (10–11).

Water that comes in (1e) is heated in the various heat exchangers before being introduced into the saturator (5e).

As in a steam injection gas turbine cycle, water intake increases the mass flow passing through the turbine, which participates in the performance gain.

By varying humidity of air leaving the saturator, it is possible to modulate the system capacity. The cycle is much simpler than a combined cycle, and does not require expensive components, so that its capital cost is relatively low (400 U.S. $/kW for an installed capacity of 300 MW).

Westinghouse has proposed a cycle variant called Cascaded Humidified Advanced Turbine Cycle (CHAT), and announced very high efficiencies (55% to 65% with a compression ratio of 80 and a turbine inlet temperature of 1500 °C).

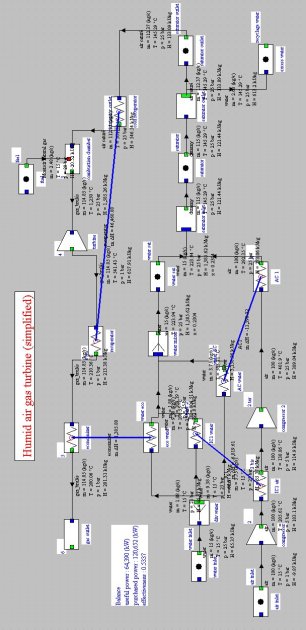

The cycle diagram in Thermoptim is given Figure below. This cycle uses the saturator presented in the model library. Since the amount of makeup water needed is not a priori known, we have provided a flow of water supply larger than required. At the saturator outlet, a divider allows to separate excess water which is recycled.

Exercises and personal activities

An exercise is proposed. Its correction will provide the Thermoptim files allowing you to model the cycle presented above.

References

P. CHIESA, G. LOZZA, E. MACCHI, S. CONSONNI, An assesment of the thermodynamic performance of mixed gas-steam cycles : part B –water injected and HAT cycles, Journal of Engineering for Gas Turbines and Power, vol. 117, pp. 499–508, july 1995.

M. NAKHAMKIN, E.C. SWENSEN, J.M. WILSON, G. GAUL, M. POLSKY, The Cascaded humified advanced turbine (CHAT), Journal of Engineering for Gas Turbines and Power, vol. 118, pp. 565–571, july 1996.