Geothermal energy

Principle

Geothermal energy comes from the gradual temperature increase as one penetrates deeper into the earth's crust, either because of the natural gradient (3°C/100 m, with an average flux of 60 mW/m2), or because of geophysical singularities (high temperature natural geothermal reservoirs of porous rock).

It is customary to distinguish three broad categories of reservoirs, according to their temperature levels:

high temperature (>220 °C);

intermediate temperature (100–200 °C);

low temperature (50–100 °C).

In the first case, the geothermal fluid can be essentially composed of water or steam, in the other two it is water, optionally under pressure. A special feature of geothermal fluid is that it is never pure water: it also includes many impurities, corrosive salts (the concentration limit for an operation to be possible is equal to 1.5 mol/kg) and non-condensable gas (NCG) in varying amounts (0.1-10%). We shall see that this feature imposes constraints on thermodynamic cycles that can be used.

For environmental reasons, the geothermal fluid should generally be reinjected into the reservoir after use, but it is not always the case.

The thermodynamic conversion of geothermal energy uses four main techniques:

plants called “direct-steam” can be used if the geothermal fluid is superheated steam that can be directly expanded in a turbine. Historically, this type of plant was first implemented in Larderello in Italy since 1904;

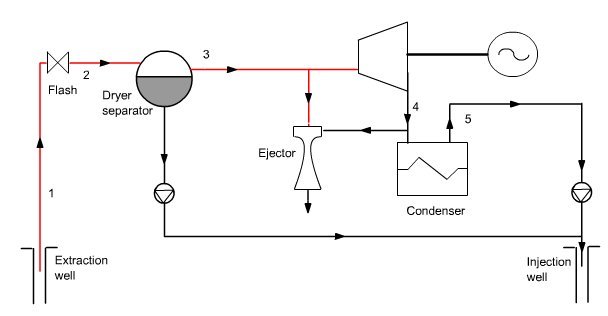

flash vaporization power plants can exploit sites where geothermal fluid is in the form of pressurized liquid or liquid-vapor mixture. Today it is the type of plant most used. Geothermal fluid begins by being expanded in a chamber at pressure lower than that of the well, thereby vaporizing a portion, which is then expanded in a turbine;

systems known as binary use a secondary working fluid, which follows a closed Hirn or Rankine cycle, the boiler being a heat exchanger with the geothermal fluid;

fluid mixture systems, such as Kalina cycle, a variant of binary systems where the working fluid is no longer pure but consists of two fluids to achieve a temperature glide during vaporization.

Mixed or combined cycles can use both a direct or flash system and a binary system. In what follows,

we present these different cycles modeled in Thermoptim.

Direct-steam plants

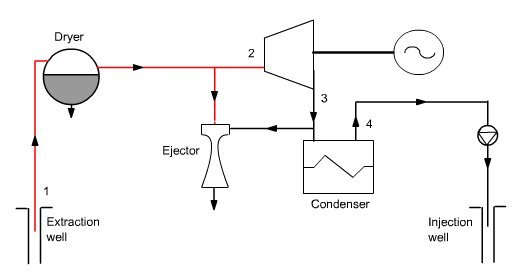

Direct-steam cycle is very close to that of Hirn or Rankine. The main difference comes from the need to extract the NCG in order to condense water at the turbine outlet, which allows the steam to be expanded at pressure below the ambient. Depending on circumstances, the extraction is done using an ejector driven by geothermal steam, or a compressor coupled to the turbine.

Generally, the condenser cooling is provided by a cooling tower whose makeup water may be taken from the condensate itself. As mentioned above, this type of plant requires the existence of dry steam in production wells, which is exceptional: the only known sites that have this property are Larderello in Italy and the Geysers in NW California.

Simple flash plant

Generally, the well contains a low quality (below 0.5) liquid-vapor mixture, which cannot be sent directly to the turbine.

If the initial pressure is suffi cient, a solution is to partially expand the mixture in order to vaporize a portion, which is then sent to the turbine, while the liquid fraction is reinjected. As in the case of direct-steam plant, the vapor phase typically contains a significant amount of NCG to be extracted if we want to condense water at the turbine outlet. Note that steam through the turbine is distilled water which can sometimes be valorized notably as drinking water.

Double flash plant

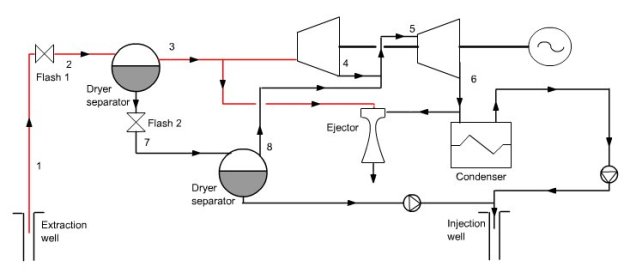

In some cases, if the pressure at the well outlet is sufficient, it is possible to achieve a double flash, which allows steam to be obtained at two different pressure levels and increases plant performance. Theoretically, we could thus increase the number of flashes, but technological and economic constraints limit them in practice to 2.

As shown in the synoptic view of Figure below, the liquid stream, which in the previous cycle was recompressed and re-injected, undergoes this time a second flash. The liquid phase is recompressed and reinjected, while the vapor is mixed with the steam flow from the first flash expanded at the same pressure. The whole is then expanded at the condenser pressure in a LP turbine.

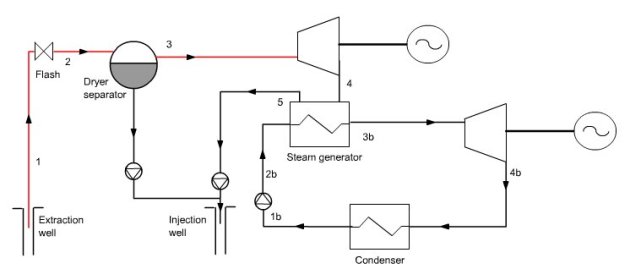

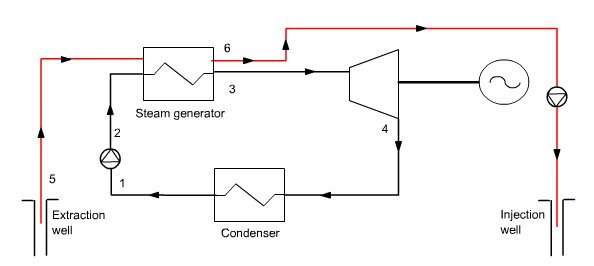

Binary cycle plant

When the temperature or pressure at the well outlet is low, it becomes impossible to make use of direct-steam or flash cycles. We then use a second working fluid, which follows a closed Hirn or Rankine cycle (with or without superheating). The geothermal fl uid then transfers its heat to the fluid before being reinjected. A cooling tower ensures condensation of the working fluid, whose choice depends on many considerations, technological, economic and environmental. Since this is often an organic fluid, it is customary to speak of Organic Rankine Cycle (ORC).

The condensation pressure and temperature of butane may be here lower than for the geothermal fluid in flash cycles because of the absence of noncondensable gases in the second cycle. Like any Hirn cycle, this cycle can be improved by judiciously introducing reheats and/or extractions.

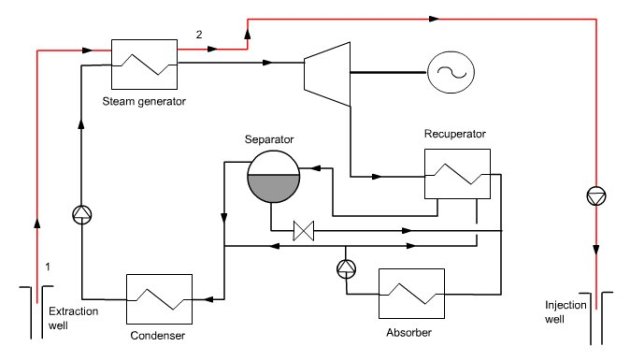

Kalina cycle

The Kalina cycle, which was presented in detailed manner in another thematic page, uses as working fluid system “water – ammonia”, which has an important temperature glide. The Kalina cycle replaces the ORC cycle of the previous example. Given the temperature glide, irreversibilities in heat exchanger between the geothermal fluid and the working fluid are reduced, and geothermal heat better used.

Combined cycles

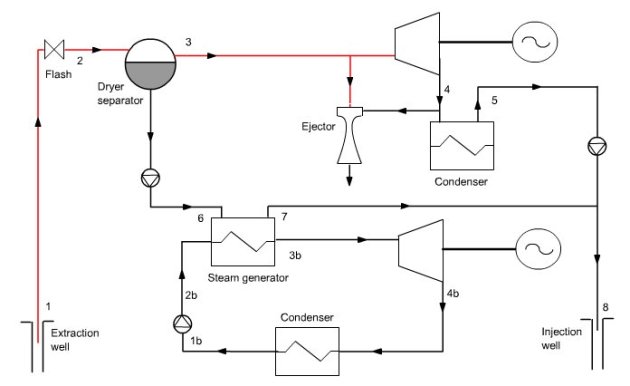

As we have seen, one of the constraints encountered in condensation of direct-steam or flash cycles is the need to extract NCG, resulting in significant parasitic energy consumption.

An alternative is to use a combined cycle, combining direct-steam or flash cycle with an ORC, the steam leaving the turbine being at a pressure higher than atmospheric, and being cooled in the boiler of the second cycle.

Mixed cycle

One major drawback of flash cycles is that they exploit only a small share of the total flow of geothermal fluid, the one corresponding to the vapor fraction after the flash, the liquid fraction being reinjected. Mixed cycles valorize the geothermal fluid, using the liquid fraction to provide the energy necessary for an ORC cycle. One can thus obtain a total efficiency well above that of a flash cycle. Of course, if the topping cycle of a combined cycle is the flash type, it is possible to associate a second ORC cycle of the mixed type.

The gain is somewhat lower than that obtained in the combined cycle, but already quite significant. Note that it would indeed be quite possible to add this butane cycle on the combined cycle, which would improve performance.

Book reference

Chapter 31 Part 4

An excerpt of this chapter can be dowloaded with the authorization of CRC Press .

Guidance page for practical work

Guidance page for practical work 9: electricity production from geothermal energy (setting out and correction )