Vapor compression refrigeration exercises (setting out)

The exercises below are available to develop your modeling capability with Thermoptim. The statements being very brief, the diagram is provided in each case. Once the model is established, you can do sensitivity studies to analyze the influence of various parameters on the cycle performance.

The corrections are accessible to authentified teachers. The files provided are for Windows. As these are text files, it may be necessary to convert them for Macintosh or Linux.

1) simple refrigeration cycle

A simple R134a refrigeration cycle operates between a suction pressure of 2 bar and a condenser pressure of 9 bar. The polytropic efficiency of the compressor is equal to 0.75.

2) cycle with superheating and subcooling

This is a modification of the previous cycle which operates between a suction pressure of 2 bar and a condenser pressure of 9 bar. The polytropic efficiency of the compressor is equal to 0.75. Before entering the compressor, the gas is superheated by 5 K above the saturation temperature, before entering the valve, the liquid is subcooled to 5 K.

3) simple refrigeration cycle

A simple R134a refrigeration cycle operates between a suction pressure of 1 bar and a condenser pressure of 12 bar. The polytropic efficiency of the compressor is equal to 0.75.

4) cycle with heat exchanger

This is a modification of the previous cycle, with the introduction of a heat exchanger to produce superheating and subcooling. (pressures: 2 et 9 bar)

5) refrigeration cycle (Two-stage cycle)

In this two-stage R134a refrigeration cycle with intercooling, the compression is split and the refrigerant cooled from 24 °C to 10 °C by an external heat sink. The pressures are 1, 3.5 and 12 bar.

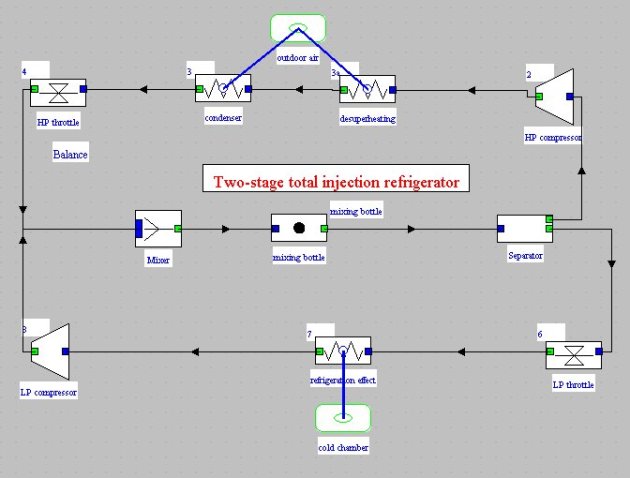

6) total injection cycle

This is a variant of the previous cycle where the vapors leaving the LP compressor and the two-phase fluid leaving the HP expansion valve are mixed in a bottle which acts like a capacitor and a separator, the vapor being sucked into the HP compressor, while the liquid passes through the LP expansion valve.

7) partial injection cycle

This partial injection cycle is a modification of the previous cycle, in which only the vapor phase exiting the high pressure expansion valve is mixed with the steam coming out of the low pressure compressor (pressures: 1, 3.5 et 12 bar)

8) medium pressure evaporator cycle

This medium pressure evaporator cycle is a modification of the total injection cycle, wherein a portion of the liquid leaving the IP separator is directed to a second evaporator to cool at a temperature corresponding to the intermediate pressure IP. In this example, one fifth of the total flow of liquid exiting the HP expansion valve is directed to the IP evaporator.

9) medium pressure evaporator cycle

This is a modification of the previous cycle, 4/5of the total flow of liquid leaving the HP expansion valve is this time directed to the IP evaporator.

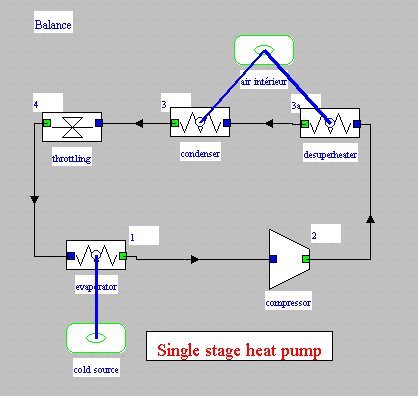

10) heat pump cycle

Example of heat pump used for space heating. This is a simple modification of the R134a refrigeration cycle treated in the Thermoptim getting started guide. It operates between a suction pressure of 1.5 bar and a condenser pressure of 9 bar, with superheating and 5 K subcooling 10 K.