Generation of Thermoptim model equations for combined cycles

Single pressure combined cycle

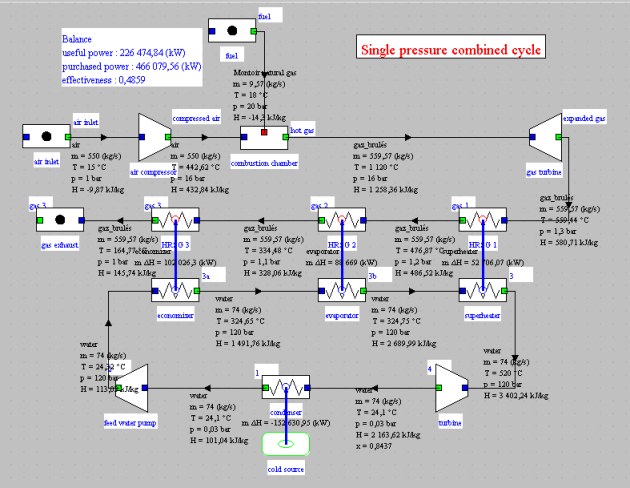

This combined cycle is the subject of guided exploration n°C-M3-V1, which you can refer to if you want to learn about this type of cycle. Its synoptic diagram is given below:

The diagram and project files are given below. Please note that they require the use of Thermoptim in English, i.e. with the inth2.zip file of this language.

Conversion to EES format

EES is a solver developed by f-Chart, which requires a license. The conversion results in a file that can be processed by the solver. The equations for calculating the fluid properties converted to this format are given below, the others remaining unchanged:

The file that can be resolved in EES is provided below.

Dual pressure combined cycle

This cycle has been optimised using the Thermoptim pinch method. Detailed explanations on how the architecture of this cycle can be defined are given in the guidance page n°11 of this portal.

Its synoptic view is given below:

Raw equations generated

There are 257 of them. They are given in this file.

The analysis of these equations identifies 22 groups of variables and equations.

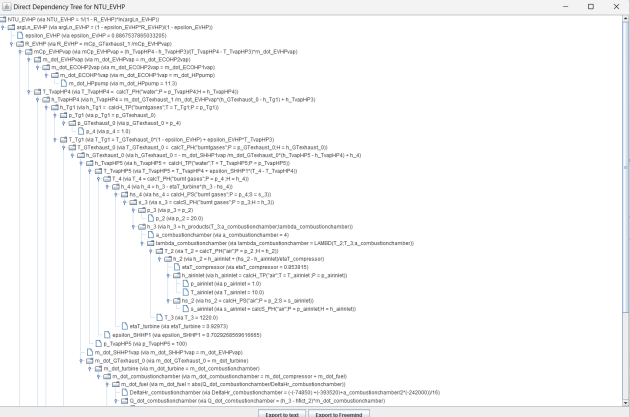

It is possible to study the direct dependencies between them.

As an example, the figure below shows the graph relating to the number of transfer units NTU of the exchanger corresponding to the high-pressure vaporizer EV_HP.

The corresponding mind map is given below.

Conversion to EES format

The file that can be resolved in EES is provided below. In the end, it has 239 equations.

The only changes to be made to the file of raw equations were the following:

removal of redundant equations, bearing in mind that it would be necessary to change the default setting of the exchangers, which corresponds to a given epsion efficiency, to replace it with the calculation of the gas outlet temperatures, those of the steam being set by the choice of pressures

parameterization of the steam economizer outlets with a subcooling of 0.5 °C, in order to ensure that a minimum temperature difference of this value exists between the inlet and outlet of the steam flow

deletion of one of the equations at the outlet of the first divisor of the gas vein, which is in fact redundant

replacement of the equations of the properties of the burnt gases using the two EES functions provided

addition of the missing equations providing the values of certain parameters

This model, which involves 239 equations, seven heat exchangers and 30 components, was thus generated from the Thermoptim model at the cost of about an hour's work.