Oxycombustion cycles

Introduction

Achieving oxycombustion consists of replacing the usual oxidizer, i.e. air, a mixture mainly of oxygen and nitrogen (resp. 21% and 78% by volume) with pure oxygen or a mixture of oxygen O2 and carbon dioxide CO2.

Oxycombustion techniques make it possible both to obtain fumes composed almost exclusively of water and carbon dioxide and to reduce very strongly the emissions of nitrogen oxides.

These are technologies already used in industry, including glass and steel.

The separation of CO2 and H2O is then done very simply by simple condensation of the water, and the absence of nitrogen also makes it possible to greatly reduce NOx emissions and the volume of fumes.

The CO2 can then be stored, and the net greenhouse gas emissions of the cycle are zero.

Despite these advantages, these technologies have so far been almost not used for electricity generation due to the difficulties and costs involved in oxygen production.

Several technical solutions exist, but the most developed today, called the Air Separation Unit, consists of separating oxygen and nitrogen from the air by cryogenic means, an operation that is both expensive and energy-consuming.

Four oxycombustion devices using this separation technique have recently been proposed: the so-called "Water cycle", Matiant, "Oxyfuel" and Graz cycles.

Their principle consists in carrying out combustions with as oxidizer a gas containing on the one hand oxygen, and on the other hand a mixture of CO2 and H2O, in various proportions depending on the case.

Under these conditions the flared gases have thermophysical properties close to those found in a gas turbine whose oxidizer is air, which makes it possible to use existing high-efficiency expansion turbines, without the need for new technological developments.

These four cycles are distinguished by their configurations, close to the regenerative gas turbines for the first two, a combined cycle for the third, and more original for the Graz cycle, whose gas and steam cycles are directly integrated instead of simply juxtaposed.

This process based on the external separation of air into oxygen and nitrogen is not the only one, however, and innovations are currently being studied, in the form of internal separation cycles.

All but two of these cycles (Water cycle and Matiant) involve both gas turbines and steam turbines.

We will just study the Oxyfuel cycle, a little simpler than the others.

Technological explanations are given in this page.

OxyFuel Cycle

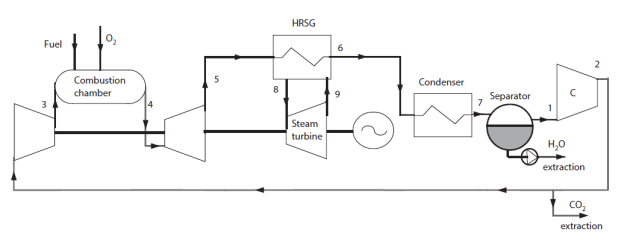

In an Oxy-fuel cycle (Figure below), at the condenser inlet (6), we get fumes containing CO2 and H2O at a pressure of 1 bar. They are cooled by an external heat sink at a temperature low enough for almost all water to be condensed (7). The condensed water is extracted from the cycle.

At the condenser outlet, a fraction of the gas composed mainly of CO2 is extracted (2), the remaining flow, equal to 35 kg/s in this example being compressed at the pressure of 40 bar in a compressor (2-3 ) before being mixed with pure oxygen (about 4.4 kg/s). This mixture is then used as an oxidizer in a stoichiometric combustion chamber (3-4) whose fuel is methane, the temperature at the end of combustion being about 1350 °C.

Fumes are expanded at 1 bar in a turbine (4-5), then cooled in a recovery steam generator (5-6) before entering the condenser, thus closing the cycle.

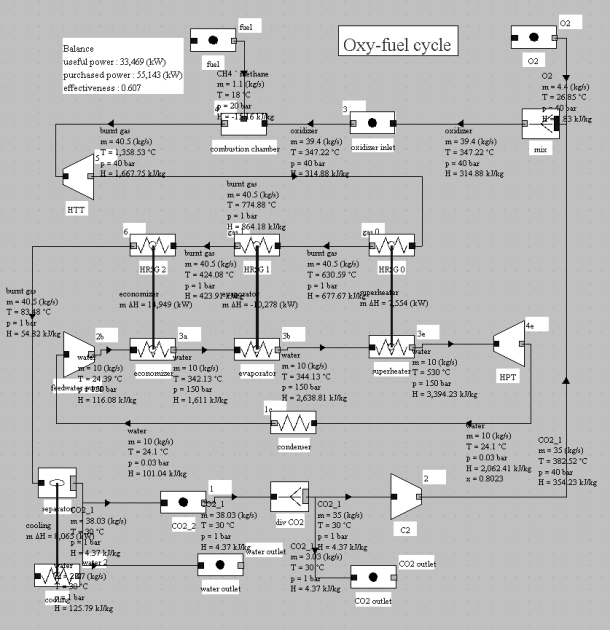

A steam cycle, working between pressures of 0.03 bar and 150 bar and 530 °C, involving a water flow of 10 kg/s, is coupled to the previous cycle to form a combined cycle. In the diagram of Figure 15.33 a simplified steam cycle is represented as a HRSG and the turbine pump and condenser are not shown nor oxygen and fuel compressors.

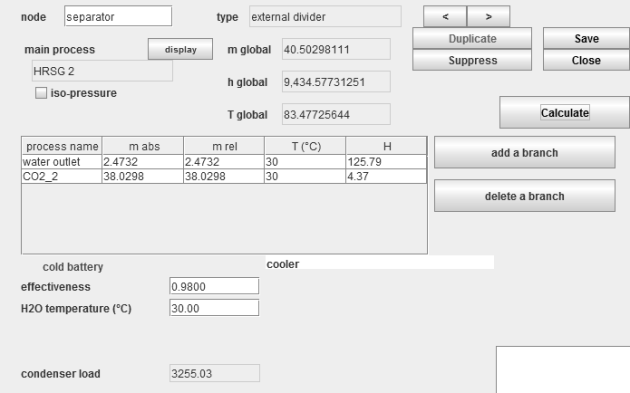

The modeling of this cycle uses an external divider to represent the condensation of mixed water vapor: the external class ColdBattery , coupled to a thermocoupler (Figure below). Its class is available in the model library.

This cycle is the subject of guided exploration (C-M4-V5).

Important note: to make this page easier for you to read, we have inserted here these guided explorations, but you should use the ones contained in the Thermoptim browser installed on your computer, because it is them that are coupled with Thermoptim and all the corresponding working files.

This model leads to the following results: power output 33.5 MW, gross efficiency 60.7%, but these excellent performances must be tempered by the "cost" of separation of oxygen from the air. The synoptic view of this cycle is given in the figure below.