Selection criteria for thermodynamic fluids

Introduction

When you are asked to select a working fluid for an application, you generally wish it to provide high energy performance, to be adapted to the operating conditions of the cycle, to be economically viable and to meet the regulations.

The criteria for selecting fluids for refrigeration cycles can obviously be different from those for Rankine cycles.

Problems occur differently in the case of designing a new installation or changing the fluid in an existing one. In the latter case, it is necessary that the thermodynamic properties of the replacement fluid are similar to those of the original, whereas in the first case the change can sometimes lead to improved performance of the facility. In any case, many technological problems must be studied, such as compatibility with lubricants, choice of the dehydrator, adjusting the expansion valve etc.

Generally, one can distinguish, in all classifications, four main categories of criteria:

performance criteria;

technical and economic criteria;

operating limit criteria ;

environmental and safety criteria.

Energy performance criteria

Numerous studies have been published in recent years, trying to connect to the energy performance the thermophysical properties of fluids, especially for ORC (Organic Rankine Cycle) energy recovery cycles.

The findings of these studies show that it is very difficult to identify such links, and that very often no fluid is satisfactory fluid at all levels.

However, it is clear that some properties can have a direct impact on the cycle in question.

Critical coordinates

The values of the critical temperature and pressure are very important. These data determine the boundary of the high pressure of the cycle. Near the critical pressure, a very small change in temperature can cause a significant change in pressure, which can influence the behavior of the system.

It is thus generally recommended to keep a sufficient "distance" between the critical point and the HP part of the cycle, except in the supercritical cycles.

Temperature glide

In some cases, the existence of a temperature glide can be an advantage in terms of heat exchange. We know that such a shift is observed in zeotrope mixtures.

In the ORC cycles for recovering heat on effluents, the temperature glide can reduce irreversibilities. If the heat source is at a constant temperature (condensing vapor), it may however be preferable to maintain a constant fluid evaporation temperature.

Expansion slope of the working fluid

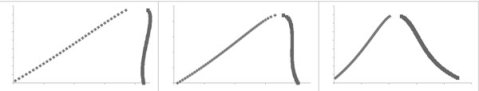

We can distinguish three types of fluids: dry fluids, isentropic fluids and wet fluids. They differ by the value δ of the expansion slope in the entropy chart, defined by δ = dS / dT curve of vapor saturation.

if δ> 0, the fluid is called "dry";

if δ = 0, the fluid is called "isentropic";

if δ <0, the fluid is called "wet".

Specifically, the steam saturation curve of "dry" fluids has a positive slope, that of "isentropic" fluids is infinite and "wet" fluids have a negative slope. This results in the three forms of saturation curves shown in the figure below (dry fluid on the left, isentropic in the middle, and wet fluid on the right).

It is better to run turbines in the vapor zone rather than in the vapor-liquid equilibrium zone due to the formation of drops of liquid that may have an abrasive effect and lower the isentropic efficiency. If the steam is saturated at the turbine inlet, only "dry" and "isentropic" fluids can meet this condition. In the case of the use of a "wet" fluid, superheating is preferable.

Moreover, the superheating is not recommended for all types of fluids. In some cases, it may be a way to increase the efficiency of the system, but this is not always true. In general, superheating is advantageous for a "wet" fluid, but less for a "dry" fluid. Thus, the type of fluid chosen has an influence on the architecture of the energy system.

For ORC cycles, "isentropic" or "dry" fluid is generally preferred. However, note that "dry" fluid is not necessarily the perfect fluid because it can remain highly superheated after expansion. We must then consider using a regenerator to recover the thermal power by desuperheating the fluid to saturation, but it can present technological difficulties and increase costs.

These conclusions are also valid for a refrigeration or heat pump cycle, wet fluid leading to greater fluid superheating than a dry one.

Modelling of fluids

Given that the mere knowledge of the thermophysical properties of fluids is not sufficient to determine the energy performance of a facility, it is necessary to model the system under study in order to get it, and therefore have a fluid thermodynamic model.

Many equations of state (EoS) have been proposed and continue to be developed. Among the most used are the cubic equations, whose main advantage is that they can be formally resolved, but which have different limits that association models can often exceed.

Technical and economic criteria

Some thermophysical properties of the fluid have a direct impact on the costs of equipments. We quote here a few.

Specific volume and latent heat

A low specific volume and a significant latent heat allow:

to absorb more energy during the evaporation;

to reduce the required flow, thus reducing the size of the facility;

to reduce the volume of steam at the exit of an ORC turbine, thus to reduce its size.

Transport properties

The transport properties, namely the viscosity and the conductivity, determine the convective heat transfer of the fluid in question. The convective heat transfer coefficient of the fluid is, in particular, proportional to the thermal conductivity. These two parameters are required when designing heat exchangers.

Speed of sound

The speed of sound of the fluid limits the flowrate of fluid circulating in a turbine. This parameter therefore directly influences the size and hence the cost of an ORC turbine.

Operating limit criteria

The operational maintenance of the machine imposes limits on certain physical characteristics of the fluids. These criteria are the melting temperature and the pressure of condensation and evaporation.

Melting temperature

For machines in which some components are located outside, the fluid temperature can drop quite low in winter. As the fluid must in no case solidify, a very low melting temperature is strongly recommended in this case.

Condensation pressure

Ideally, the fluid should condense or evaporate at a pressure higher than 1 bar to prevent entry of air into the system.

Evaporation pressure

Evaporation pressure must remain moderate if possible, otherwise the risk of leakage is increased as well as the risk of explosion.

Environmental and safety criteria

Working fluids must comply with environmental standards and safety of operators. The criteria related to the environment and the safety include the following.

GWP and ODP

Environmental regulations have tightened over the last two decades. The fluid selection must follow the standards of environmental protection in place in order to build a sustainable cycle for decades to come. It is therefore preferable that the fluid has zero Ozone Depletion Potential (ODP) and as low as possible Global Warming Potential (GWP).

Toxicity and flammability of the fluid

To ensure operator safety, it is preferable to use a non-toxic and non-flammable fluid.