Introduction

In this overview, we will present, without being exhaustive, the main types of nuclear reactors. These reactors differ by fuel type, neutron spectrum, moderator, coolant, cycle (direct/indirect), and thermodynamic fluid used, among other characteristics.

First, we will present the main reactors used for electricity production that use steam as the thermodynamic fluid. Then, we will examine those that use gas as the working fluid.

Note

This guided exploration is part of the digital resources of the Thermoptim-Unit portal. Additional information on nuclear reactors and their associated thermodynamic cycles can be found here.

Please note that we will limit ourselves here to a brief presentation of the corresponding thermodynamic cycles, indicating only their type and capacity, the pressure and temperature levels reached, and the efficiencies achieved.

Reactor containment

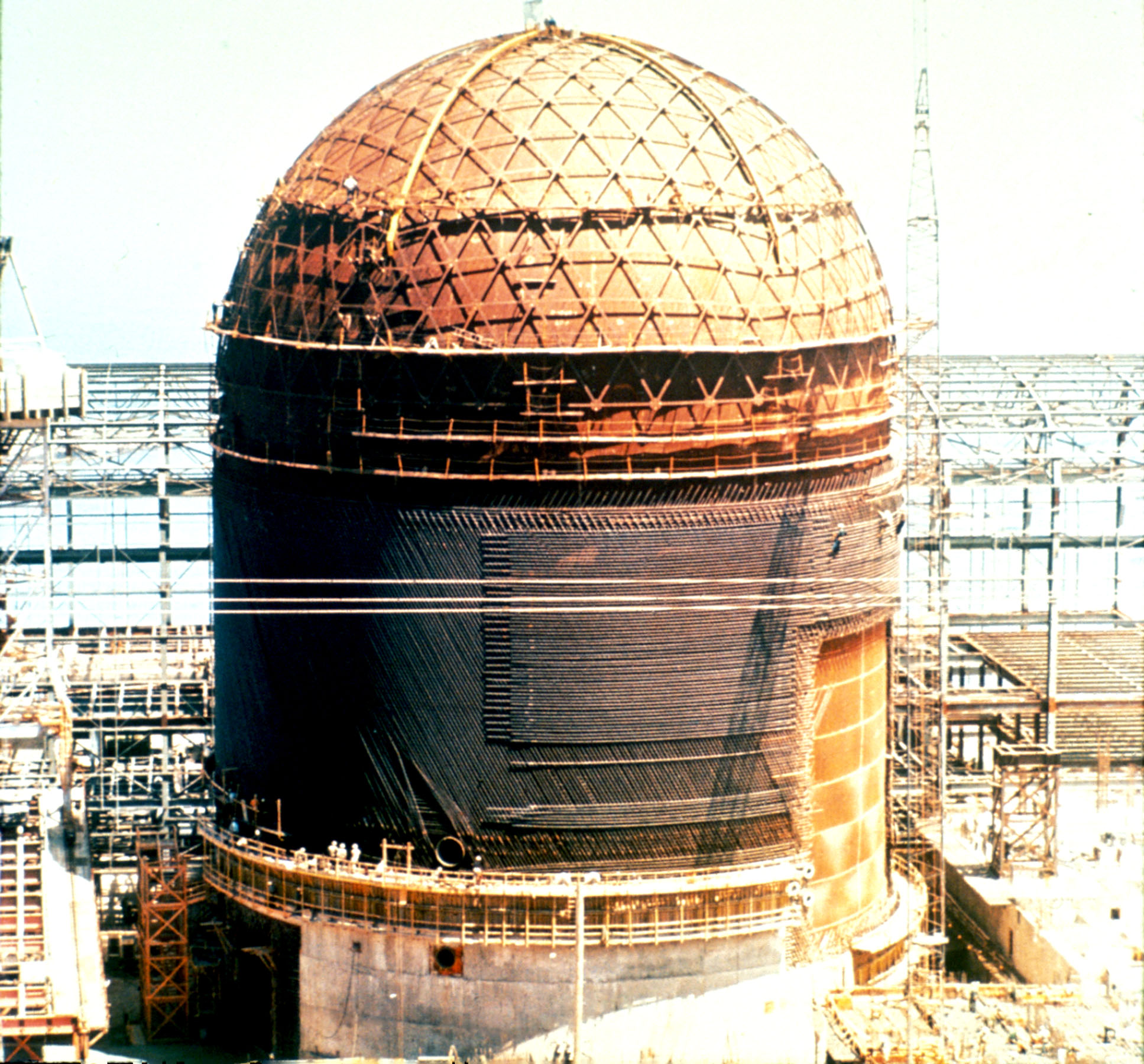

In all reactors, the core is placed in a containment vessel designed to limit the release of radioactive materials resulting from the fission reaction. The thermodynamic cycle is mostly located outside of this vessel, with the coolant transferring the heat.

The containment vessel plays an essential role in the safety and security of nuclear reactors by limiting the consequences of accidents and protecting the environment and public health. It is a fundamental component of the safety systems of nuclear installations, ensuring the containment of radioactive substances, protection against external threats, control of pressure and temperature, acoustic and thermal insulation, and facilitating maintenance and waste management operations.

This photo shows a containment vessel under construction.

Pressurized Water Reactors (PWRs)

Principle of operation

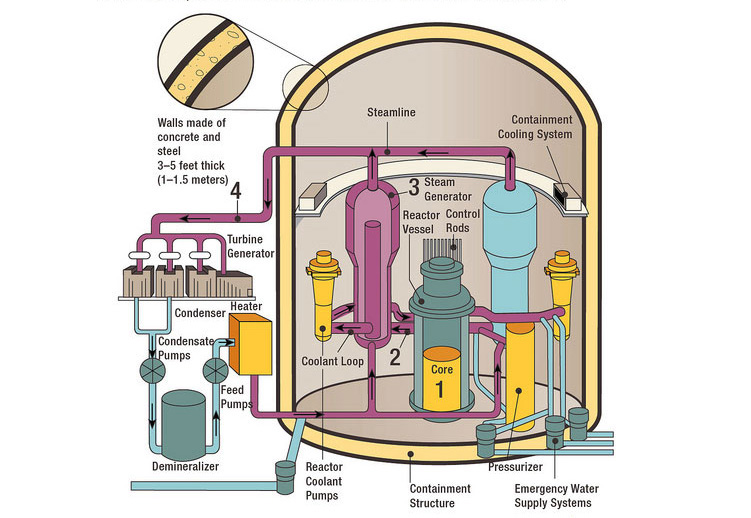

Pressurized Water Reactors (PWRs), which are used in the majority of nuclear power plants around the world, use high-pressure water (around 155 bars) as both a coolant and a moderator. The water circulates in the reactor core at this pressure and at a temperature of around 315°C, transferring the heat produced by nuclear fission to a secondary circuit via a steam generator (SG).

This secondary circuit includes a turbine, a condenser often cooled by a cooling tower, and a pump. The heat produced is used to heat water under pressure and generate steam, which is then expanded in a turbine coupled to an electrical alternator. This cycle is known as a Rankine or Hirn cycle.

Main characteristics

Moderator |

The water itself serves as a moderator by slowing down the neutrons emitted during fission. |

Coolant |

High-pressure water also serves as a coolant to transfer the heat. |

Fuel |

Enriched uranium is generally used as fuel. |

Electrical power |

PWRs can vary in capacity, ranging from a few hundred megawatts electric (MWe) to over 1600 MWe. |

Pressure and temperature levels |

PWRs operate at high pressures, typically around 150-160 bars, with primary circuit temperatures reaching around 300°C. |

Efficiency |

PWRs typically have thermal efficiencies of around 33-36%. |

Countries concerned |

Many countries use PWRs, including the United States, France, China, the United Kingdom, Russia, and Japan. |

VVER Reactors

Principle of operation

VVER (Vodo-Vodyanoi Energetichesky Reactor) reactors, also known as Russian pressurized water reactors, are used in several countries, including Russia and other former Soviet Union countries, as well as in some countries in Eastern Europe and Asia./p>

Main characteristics

Moderator |

light water |

Coolant |

VVER reactors use water as a coolant to transfer the heat produced by nuclear fission. |

Fuel |

VVER reactors typically use enriched uranium as fuel, in the form of uranium dioxide (UO2) contained in fuel rods. |

Electrical power |

The capacity of VVER reactors can range from a few hundred MWe to over 1 GW. |

Pressure and temperature levels |

VVER reactors operate at pressures between 100 and 160 bars, with primary circuit temperatures typically reaching between 290°C and 330°C. |

Efficiency |

The efficiencies of VVER reactors are between 32% and 37%. |

Countries concerned |

Russia and other countries of the former Soviet Union, as well as in some countries in Eastern Europe and Asia. |

Boiling Water Reactors (BWRs)

Principle of operation

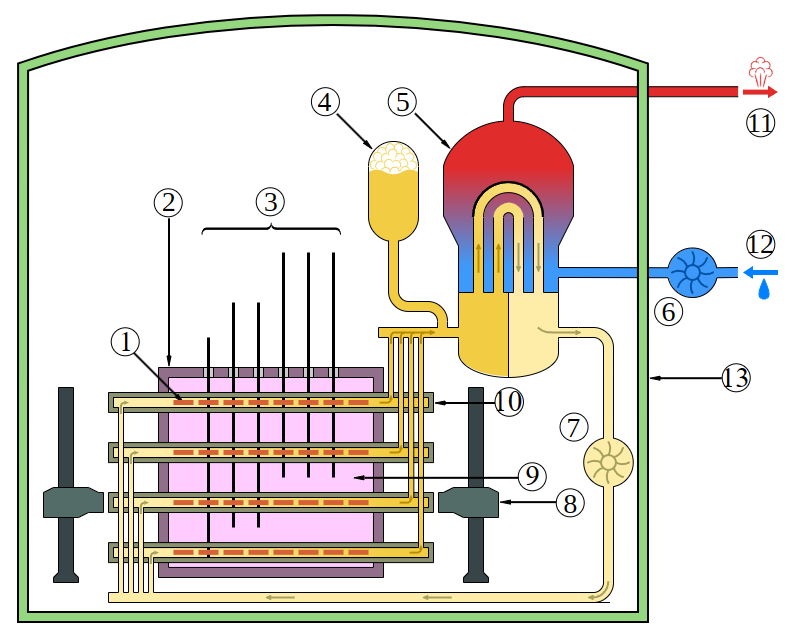

Like PWRs, Boiling Water Reactors (BWRs) use water as both a coolant and a moderator. However, in this technology, the water boils directly in the reactor core at a pressure of around 70 bars and a temperature close to 285°C, producing steam that drives a turbine without the need for a secondary circuit. A condenser and a pump complete the cycle.

As shown in the figure, the steam generator is absent in this type of reactor.

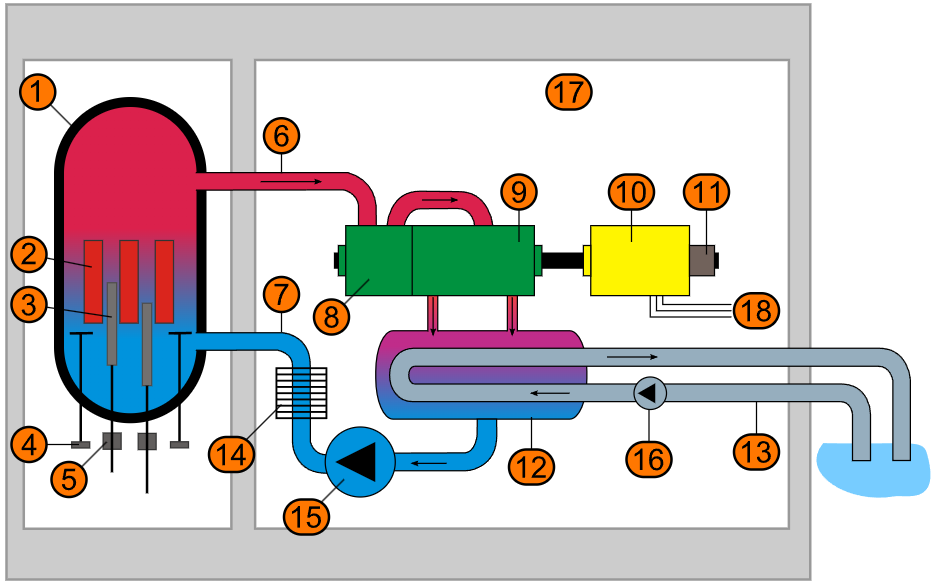

The containment vessel is located on the left, housing the core cooled by pressurized water. On the right, we see the thermodynamic cycle, with the turbine in green (8-9), below which are the condenser (12) and the pump (15), and the alternator in yellow (10).

Main characteristics

Moderator |

The water serves as a moderator by slowing down the neutrons. |

Coolant |

The boiling water transfers the heat produced to the turbine. |

Fuel |

Enriched uranium is generally used as fuel. |

Electrical power |

BWRs have a capacity range similar to that of PWRs, from a few hundred MWe to over 1600 MWe. |

Pressure and temperature levels |

BWRs operate at slightly lower pressures than PWRs, typically around 70-80 bars, with primary circuit temperatures reaching around 285-290°C. |

Efficiency |

BWRs have thermal efficiencies comparable to those of PWRs, typically around 33-36%. |

Countries concerned |

BWRs are also widely used around the world, including in the United States, Sweden, Germany, Finland, Japan, and Switzerland. |

RBMK Reactors

Principle of operation

RBMK (Russian: Reaktor Bolshoy Moshchnosti Kanalny, "high-power channel-type reactor") reactors are graphite-moderated boiling water reactors primarily used in Russia.

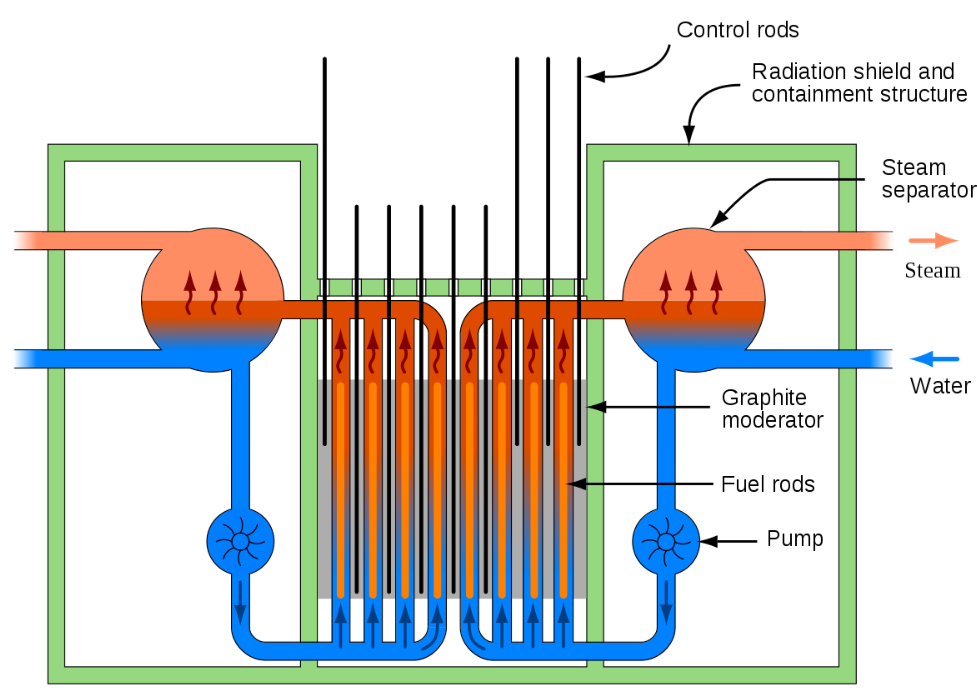

This figure shows the containment vessel, with the core in the central part, traversed by pressurized water which vaporizes, and the steam exiting at the upper part, both on the right and left.

They differ from BWRs mainly by their moderator.

It should be noted that RBMKs had serious safety and design flaws, which were highlighted by the Chernobyl accident in 1986. Since that accident, many improvements have been made to enhance their safety and reliability.

One of the characteristics of these reactors is the ability to extract or add fuel without shutting them down.

Main characteristics

Moderator |

RBMKs use graphite as a moderator to slow down neutrons. |

Coolant |

Ordinary water is used as a coolant to transfer the heat produced by nuclear fission. |

Fuel |

RBMKs typically use natural uranium as fuel, in the form of uranium dioxide (UO2) contained in fuel rods. |

Electrical power |

The first RBMK reactors had a nominal capacity of around 1000 MWe. However, later versions were designed for a higher nominal capacity, up to around 1500 MWe. |

Pressure and temperature levels |

RBMKs operate at moderate pressures, with typical values around 70 bars. The temperatures in the reactor core can vary, but they are generally maintained at high levels to ensure optimal operating efficiency. |

Efficiency |

The efficiencies of RBMK reactors can vary, but they are generally comparable to those of other types of boiling water reactors, with typical thermal efficiencies between 30 and 35%. |

Countries concerned |

Russia and other countries of the former Soviet Union, as well as in some countries in Eastern Europe and Asia. |

Supercritical Water-Cooled Reactors (SCWRs)

Principle of operation

To significantly increase the efficiency of steam-water cycles of the PWR or BWR type, it is possible to use supercritical cycles (SuperCritical Water Reactor), where the pressure of the water exceeds the critical pressure of 221.2 bars.

While in PWR reactors and those with fast neutrons cooled by sodium, a primary cooling circuit is essential due to the change of state of the steam, this could be eliminated in this type of supercritical cycle, similar to BWR reactors, where the thermodynamic fluid also serves as the reactor cooling fluid, simplifying the system significantly.

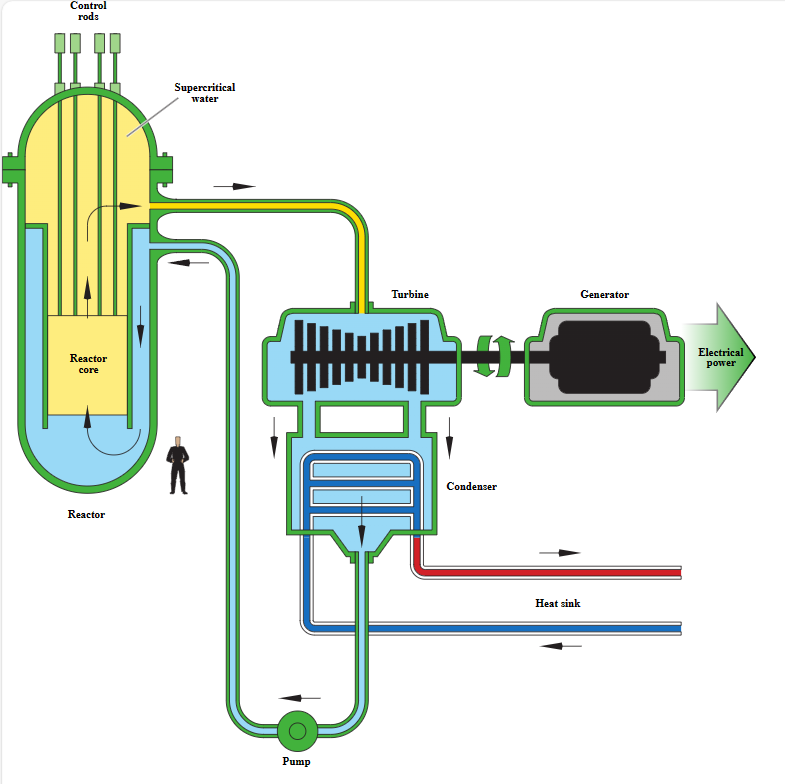

On the left of this figure is the core, traversed by pressurized water which vaporizes. The steam exits the core on the right at the top and is directed towards the turbine coupled to the alternator, underneath which are the condenser and the pump.

The envisaged cycle would achieve an efficiency of 45%, with a turbine inlet temperature ranging from 510 to 550°C and a pressure of 250 bars. Two versions of the reactor are envisaged, one with thermal neutrons and the other with fast neutrons.

Main characteristics

Moderator |

water if it uses thermal neutrons. |

Coolant |

supercritical water (between the liquid and gaseous states). |

Fuel |

enriched uranium oxide. |

Electrical power |

1,000 to 2,000 MWe. |

Pressure and temperature levels |

pressure of 250 bars and turbine inlet temperature of 510 to 550°C. |

Efficiency |

40 to 45%. |

Countries concerned |

Canada, China, South Korea, United States, Russia. |

Advanced Gas-cooled Reactors (AGRs)

The first nuclear reactors cooled by gas were known as UNGG (Uranium Naturel Gaz et Graphite) in France and Magnox in the United Kingdom. They used natural uranium metal as fuel, graphite as a moderator, and pressurized carbon dioxide as a coolant.

The Magnox design was later improved by using slightly enriched uranium as fuel and stainless steel as cladding. This new reactor design was named the Advanced Gas-cooled Reactor (AGR). AGRs have been the backbone of the UK's nuclear power generation since the 1980s.

Principle of operation

In this type of reactor, the heat produced by nuclear fission is utilized to heat carbon dioxide, which is then used to produce steam and drive a turbine.

AGRs utilize carbon dioxide as a coolant and graphite as a moderator.

The fuels used are natural uranium for the old Magnox reactors and enriched uranium for the AGR reactors.

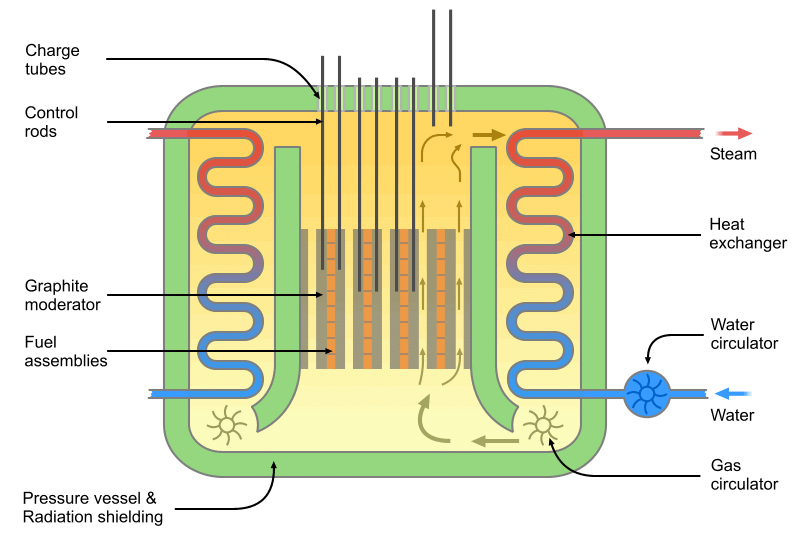

This figure illustrates the containment vessel, with the core located centrally and cooled by CO2, which transfers heat to an exchanger traversed by pressurized water, causing it to vaporize. The steam exits from the upper part, on both the right and left sides.

In the primary circuit of an AGR, the pressure of the CO2 generally ranges between 6 and 42 bars, and the temperature is maintained around 650°C.

Main characteristics

Moderator |

Graphite is used as a moderator to slow down neutrons. |

Coolant |

Carbon dioxide is used as a coolant to transfer the heat produced. |

Fuel |

Natural or slightly enriched uranium is generally used as fuel. |

Electrical power |

AGRs are generally designed to produce electricity on a large scale for the power grid, with an electrical power output ranging from several hundred MWe to over 1 GWe. |

Pressure and temperature levels |

The pressure of the steam in the secondary circuit of an AGR is around 170 bars, and the temperature is around 550°C. |

Efficiency |

The efficiency is around 40%. |

Countries concerned |

Reactors using this principle are implemented in several countries, including the United Kingdom, France, Germany, Italy, and Japan. |

Pressurized Heavy Water Reactors (PHWRs) or CANDUs

Heavy water

Heavy water, also known as deuterium oxide (D2O), is a variation of ordinary water (H2O) in which almost all of the hydrogen atoms are replaced by deuterium, an isotope of hydrogen with two neutrons instead of one.

Deuterium serves as an excellent moderator because it effectively slows down neutrons, similar to hydrogen, but without absorbing them in the process. However, deuterium occurs naturally in water in only low proportions (0.015%) and its concentration is costly.

Pressurised Heavy Water Reactors (PHWRs), utilize heavy water as both a moderator and a coolant. Thanks to the efficient moderation provided by heavy water, these reactors can use natural uranium as fuel.

This technology is commonly known as CANDU (Canada Deuterium Uranium).

Principle of operation

In this type of reactor, the heat generated by nuclear fission is employed to heat heavy water, which is subsequently converted into steam to drive a turbine.

One noteworthy feature of these reactors is the ability to extract or add fuel without the need for shutdown.

On the left side of the figure, we observe the containment building with the core cooled by heavy water, transferring heat to a secondary circuit (not depicted here) via a steam generator.

The fuel is housed within a calandria containing heavy water, and a specialized device facilitates its handling.

Main characteristics

Moderator |

Heavy water is used as a moderator to slow down neutrons. |

Coolant |

Heavy water is also used as a coolant to transfer the heat produced. |

Fuel |

Natural or slightly enriched uranium is generally used as fuel. |

Electrical power |

They have a power output that generally ranges from 600 to 2100 MWe. |

Pressure and temperature levels |

These reactors operate at a pressure of around 100 bars and a primary circuit temperature of around 310°C. |

Efficiency |

The typical efficiency is around 30%. |

Countries concerned |

Reactors using this principle are implemented in several countries, including Canada, India, Argentina, China, South Korea, and Romania. |

Fast Neutron Reactors (FNRs)

Principle of operation

Fast Neutron Reactors (FNRs) utilize fast neutrons without a moderator to induce fission. This term encompasses a broad range of reactors.

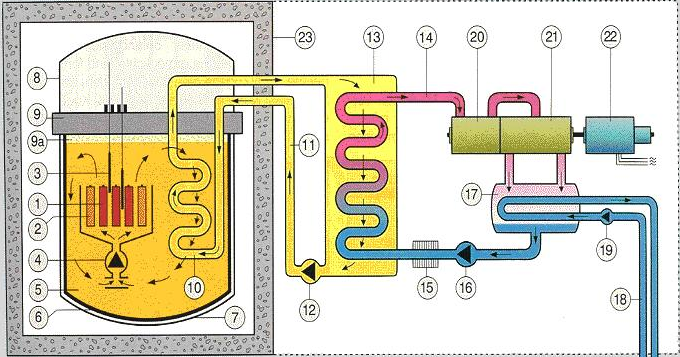

They commonly employ liquid sodium as a coolant, operating at temperatures ranging from 520-550°C and pressures close to atmospheric. The selection of this coolant imposes significant technological constraints, particularly regarding reactivity with water and air: sodium is a highly reactive metal that reacts vigorously with water and air, posing risks of fires or explosions. Therefore, sodium cooling systems must be meticulously designed to prevent any sodium leakage and contact with water or air.

On the left side of the figure, the containment building houses the core cooled by liquid sodium, transferring heat to a secondary liquid sodium circuit in exchanger no. 10. This exchanger is utilized to vaporize pressurized water in steam generator no. 13. On the right side, the remainder of the thermodynamic cycle is depicted, featuring the khaki-green turbine coupled to the alternator, underneath which the condenser and pump are located.

Fast neutron reactors (FNRs) operate without a moderator, as the neutrons remain fast.

Main characteristics

Moderator |

There is no moderator in FNRs; the neutrons remain fast. |

Coolant |

Liquid sodium is used as a coolant. |

Fuel |

Uranium or plutonium can be used as fuel, sometimes in the form of mixed oxide (MOX) fuel. |

Electrical power |

FNRs can have power outputs ranging from a few MW to several hundred MW. |

Pressure and temperature levels |

In general, the pressure of the water vapor in the secondary circuit of an FNR with liquid sodium is between 40 and 180 bars, while the temperature varies between 350 and 550°C. |

Efficiency |

The thermal efficiency of FNRs depends on many factors and can vary depending on the specific design and application. Their efficiency is between 38% and 42%. |

Countries concerned |

FNRs are less common than PWRs and BWRs, but some countries such as Russia, China, India, and Japan are pursuing development programs in this area. France was at the forefront of this technology until the late 1990s, and then relaunched studies on the subject between 2010 and 2019. |

Sodium-Cooled Fast Reactors (SFRs)

Principle of operation

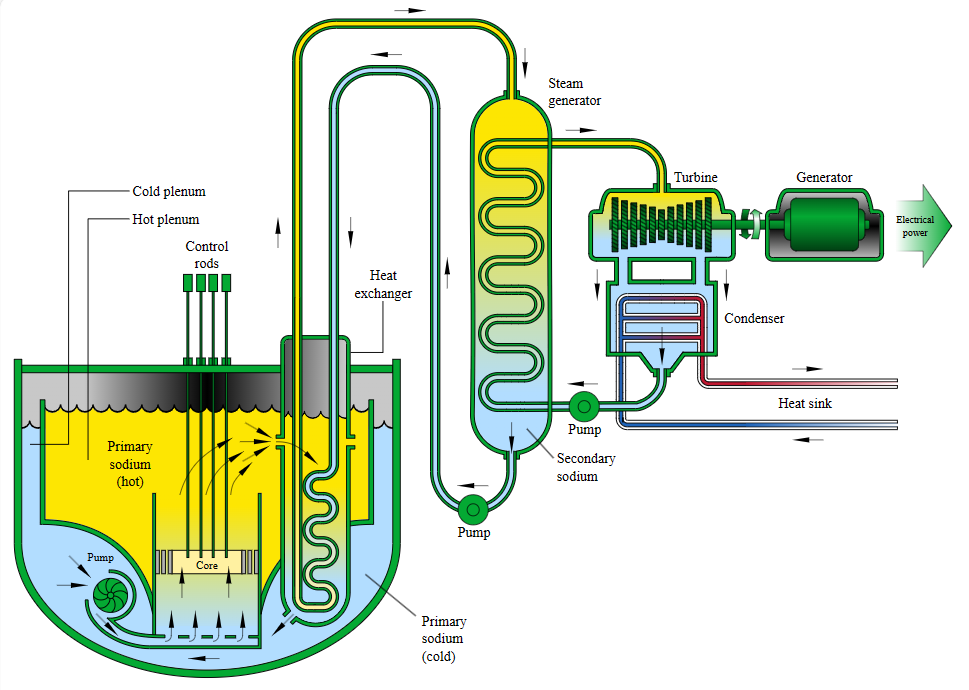

Sodium-Cooled Fast Reactors (SFRs) represent a category of FNRs specifically utilizing liquid sodium as a cooling fluid.

Various variants of sodium-cooled fast reactors are under consideration, differing in terms of capacity and fuel. In all cases, a primary cooling loop is incorporated, with the thermodynamic fluid distinct from the cooling fluid. The core outlet temperature typically reaches around 550°C.

These reactors are engineered to utilize high-level waste, particularly plutonium and other actinides, but they can also employ fissile and fertile materials, yielding significantly higher efficiencies than PWR reactors.

On the left side of the figure, the containment building depicts the core cooled by liquid sodium, transferring heat to a secondary liquid sodium circuit via a primary exchanger. This exchanger facilitates the vaporization of pressurized water in the steam generator. On the right side, the remaining portion of the thermodynamic cycle is illustrated, featuring the turbine coupled to the alternator, with the condenser and pump positioned beneath.

Main characteristics

Coolant |

Liquid sodium is used as a coolant. |

Fuel |

MOX (mixed oxides of uranium and plutonium) or uranium nitride. |

Electrical power |

600 to 1,500 MWe. |

Pressure and temperature levels |

In general, the pressure of the water vapor in the secondary circuit of an SFR is between 40 and 180 bars, while the temperature varies between 400 and 500°C. |

Efficiency |

35 to 40%. |

Countries concerned |

France, Russia, China, India, Japan, United States. |

Lead-Cooled Fast Reactors (LFRs)

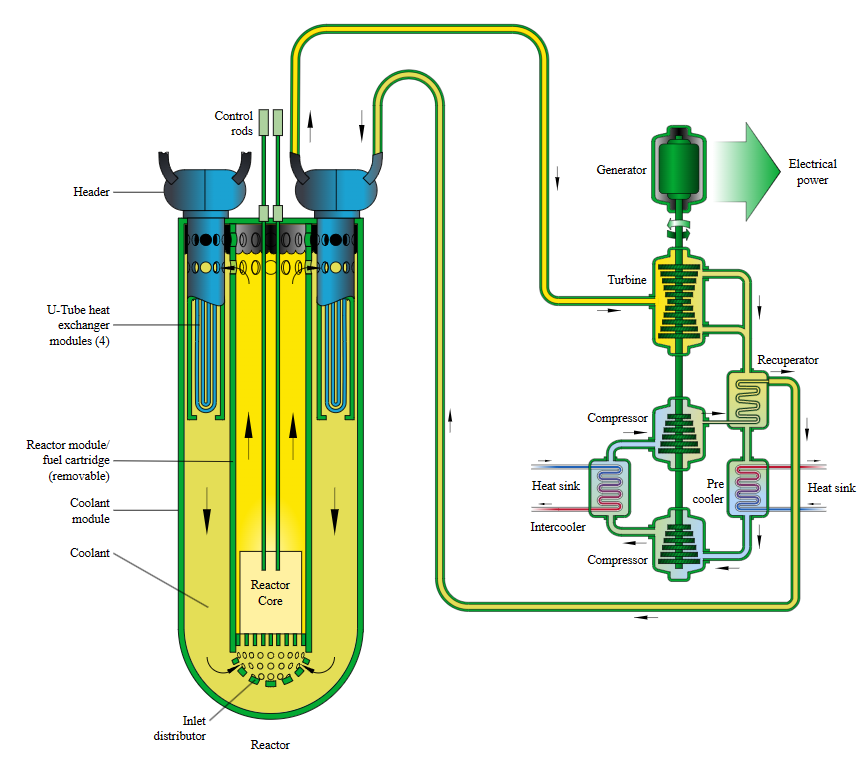

Reactors Using Gas as the Working Fluid

One of the advantages of reactors utilizing gas as the working fluid is their capability to surpass temperature limitations imposed by water-based systems, enabling high conversion efficiencies.

The thermodynamic cycles employed are typically variations of the Brayton cycle utilized in gas turbines, comprising four main components: a gas compressor, an exchanger where the coolant transfers its heat to the thermodynamic fluid, an expansion turbine, and a heat exchanger that cools the expanded fluid prior to compression.

Principle of operation

Lead-Cooled Fast Reactors (LFRs) are derived from highly efficient Russian submarine reactors, which were discontinued due to maintenance issues. Their power output typically ranged between 120 and 400 MWe.

The core outlet temperature of LFRs falls within the range of 550 to 800°C, with consideration for utilizing a gas-based thermodynamic cycle (such as He or CO2). Future developments are targeting even higher power outputs.

In the figure provided, the containment vessel is depicted on the left, housing the core cooled by lead, which transfers heat to a secondary circuit traversed by gas. This gas undergoes expansion in a turbine coupled to an alternator, then passes through a regeneration exchanger before being cooled by an external source. Subsequently, it undergoes recompression in a two-stage compressor before being redirected towards the lead exchanger.

Main characteristics

Coolant |

Lead or lead-bismuth alloy. |

Fuel |

MOX (mixed oxides of uranium and plutonium) or uranium nitride. |

Electrical power |

600 to 1,500 MWe. |

Pressure and temperature levels |

The temperature varies between 400 and 800°C. |

Efficiency |

35 to 40%. |

Countries concerned |

Russia, China, United States, South Korea. |

High Temperature Reactors (HTR)

Principle of Operation

High Temperature Reactors (HTRs) cooled by gas are thermal neutron reactors designed to operate at elevated temperatures.

In helium-cooled HTRs, the helium pressure is typically maintained at a relatively low level, between 5 and 10 bars. Helium's low density and low viscosity, coupled with its high thermal capacity, help to minimize pressure losses in the cooling circuit.

In HTRs, the secondary circuit can be configured to generate steam for driving a turbine and producing electricity.

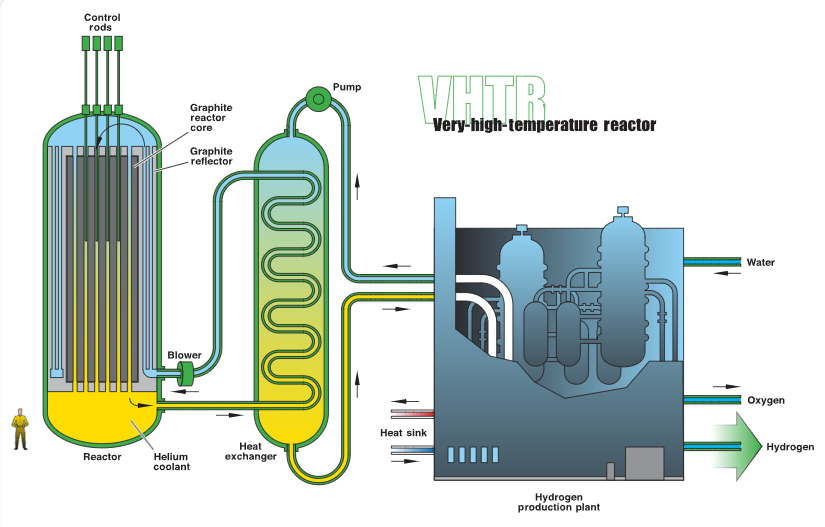

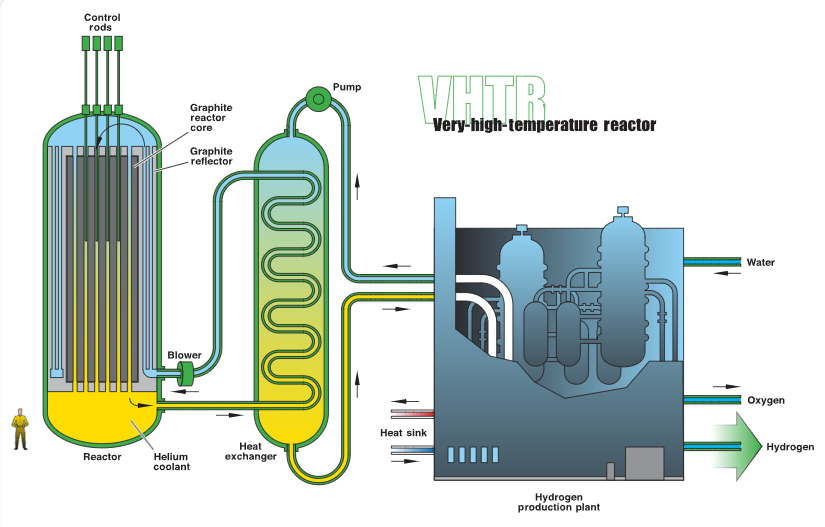

On the left side of this figure, which represents a very high-temperature reactor that will be studied later, we see the core cooled by helium. The helium transfers heat in the central exchanger to the secondary circuit, which in this example corresponds to a hydrogen production plant, the details of which are not specified.

Main Characteristics

Moderator |

HTRs generally use graphite as a neutron moderator. |

Coolant |

Helium is used as the coolant in HTRs. |

Fuel |

HTRs use TRISO fuel, composed of carbon-coated fuel particles, optimized for high temperatures. |

Electric Power |

25 to 250 MW. |

Pressure and Temperature Levels |

In general, the pressure in the secondary circuit of an HTR is between 7 and 10 bar, while the temperature ranges from 700 to 950 °C. |

Efficiency |

Their efficiency ranges between 40 and 50%. |

Countries Involved |

High Temperature Reactors are less widespread than pressurized water reactors and boiling water reactors, but some countries like Russia, China, India, and Japan are pursuing development programs in this field. |

Very High Temperature Reactors (VHTRs)

Principle of operation

Very High-Temperature Reactors (VHTRs) are High-Temperature Gas-Cooled Reactors (HTGRs) designed to operate at even higher temperatures than standard HTGRs, offering greater versatility for industrial applications.

In the figure, the core cooled by helium is shown on the left, which transfers heat to the secondary circuit associated with a hydrogen production plant, the details of which are not illustrated.

VHTRs can utilize a variety of working fluids in their secondary circuits to achieve even higher temperatures and meet specific industrial requirements. For example, some VHTRs can use helium as the working fluid in the secondary circuit.

Main characteristics

Moderator |

VHTRs generally use graphite as a neutron moderator. The choice of graphite is due to its ability to withstand high temperatures (up to 1600°C). |

Coolant |

Helium is used as a coolant in VHTRs. |

Fuel |

VHTRs use TRISO fuel particles, which are optimized for high-temperature operation. |

Electrical power |

The power output of VHTRs could potentially reach several GW. |

Pressure and temperature levels |

VHTRs operate at moderate pressures, generally below 100 bars, and at very high temperatures, exceeding 1,000°C. Their high temperature allows them to be used for various industrial processes, such as cement, glass, and steel production, coal gasification, and thermochemistry. However, given the inertia of industrial processes and the hopes placed in the development of combustibles for transportation, the main application of VHTRs could be hydrogen production. |

Efficiency |

VHTRs aim for a thermal efficiency of over 50%. |

Countries concerned |

Research on VHTRs is being conducted in several countries, including the United States, China, Germany, South Africa, and Poland, among others. |

Molten Salt Reactors (MSRs)

Principle of operation

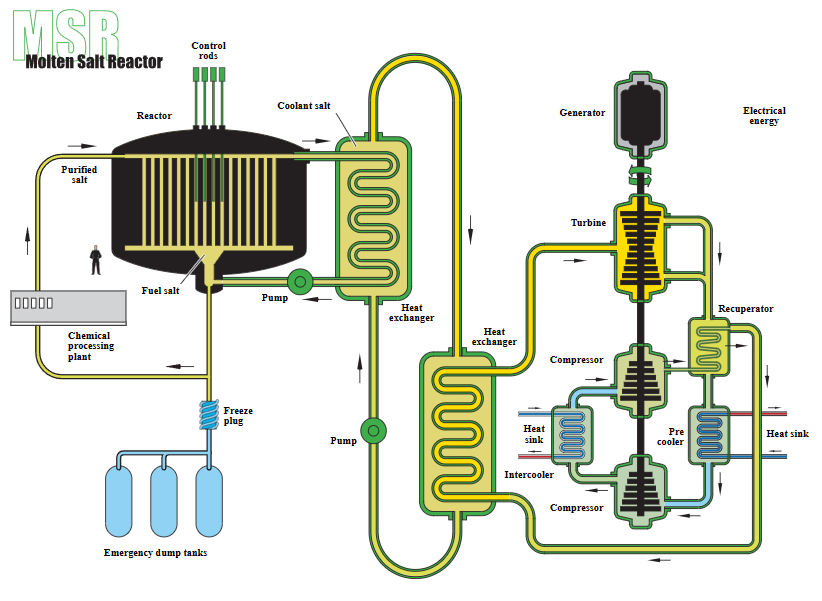

In a Molten Salt Reactor (MSR), the fuel is in liquid form, mixed with molten salts at temperatures ranging from 600 to 900°C. The nuclear fuel is dissolved in these salts, which also serve as the coolant.

The heat produced by nuclear fission is used to heat the molten salts, which then transfer the heat to a secondary circuit. This secondary circuit can use either water or gas as the working fluid, with the pressure and temperature varying based on the chosen fluid and reactor design.

The salts used in MSRs are generally fluorides or chlorides, capable of dissolving large quantities of actinides, fission products, and other nuclear elements.

The high solubility of these molten salts allows for easy adjustment of the fuel composition by adding or removing specific isotopes or elements. This design flexibility enables the optimization of neutron reactivity to favor epithermal neutrons.

While adjustments to fuel composition are possible in various types of nuclear reactors, the high solubility of fuels in MSRs provides unique flexibility. This allows for more efficient optimization of neutron reactivity using epithermal neutrons.

Favoring epithermal neutrons offers several advantages, including the possibility of transmuting long-lived nuclear waste, reducing material fatigue in the reactor, conserving fissile material, and producing medical isotopes. These benefits are particularly relevant for advanced nuclear reactors and specific nuclear applications.

The pressure of the salts in MSRs is generally maintained close to atmospheric pressure, around 1 bar. This is because molten salts are liquids at high temperatures with low volatility and do not easily vaporize.

On the left of this figure, we see the core cooled by molten salts, which transfer heat to a secondary salt circuit through a primary heat exchanger. The heat is then transferred to the secondary circuit, traversed by a gas, through a secondary heat exchanger. This gas is expanded in a turbine coupled to an alternator, then passes through a regeneration heat exchanger before being cooled by an external source, recompressed in a two-stage compressor, and redirected to the secondary heat exchanger with the molten salts.

Main characteristics

Moderator |

The moderator is graphite or the molten salts themselves. |

Coolant |

Molten salts |

Fuel |

Thorium or enriched uranium. |

Electrical power |

MSRs can be designed to produce a wide range of power outputs, from a few MW to several GW. |

Pressure and temperature levels |

Atmospheric pressure, 700°C |

Efficiency |

Around 45% |

Countries concerned |

Many countries are developing MSRs, including the United States, China, Canada, the United Kingdom, France, Russia, India, Japan, and South Korea. |

Fast Molten Salt Reactors (FMSRs)

Principle of operation

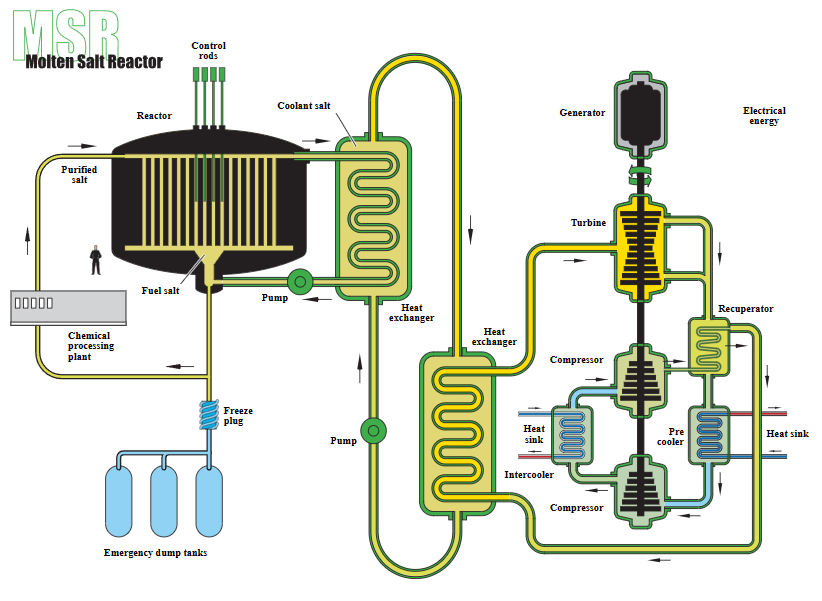

In Fast Molten Salt Reactors (FMSRs), there is no moderator.

Their secondary circuit generally uses a gaseous coolant, such as helium or supercritical carbon dioxide, rather than water.

On the left of this figure, we see the core cooled by molten salts, which transfer heat to a secondary salt circuit through a primary heat exchanger. The heat is then transferred to the secondary circuit, traversed by a gas, through a secondary heat exchanger. This gas is expanded in a turbine coupled to an alternator, then passes through a regeneration heat exchanger before being cooled by an external source, recompressed in a two-stage compressor, and redirected to the secondary heat exchanger with the molten salts.

Main characteristics

Coolant |

Molten salts, such as fluorides and chlorides, are used as a coolant. |

Fuel |

The fuel can be composed of thorium, uranium, plutonium, and minor actinides. |

Electrical power |

Their capacity could vary from a few MW to a GW or so. |

Pressure and temperature levels |

They operate at atmospheric pressures and at high temperatures, which can exceed 700-800°C in the primary circuit. |

Efficiency |

FMSRs would aim for high thermal efficiencies, similar to or higher than MSRs, around 40-50%. |

Countries concerned |

Research on FMSRs is less advanced than on MSRs, but work is being done in the United States and China, among other countries. |

Relative Sizes of Reactors

It should be noted that the size of Advanced Gas-cooled Reactors (AGRs) is much larger than that of other technologies. This is due to the properties of their moderator, which is carbon in the form of graphite.

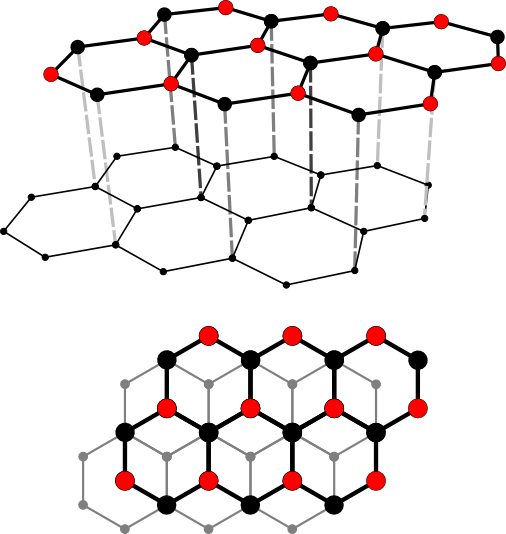

Properties of Graphite

Graphite, like diamond, is a crystalline form of carbon. It consists of layers of carbon atoms arranged in hexagons, with the layers stacked on top of each other. Each carbon atom is bonded to three other carbon atoms in the same layer, forming strong covalent bonds, while the bonds between the layers are weaker, giving graphite its layered structure.

Graphite is an abundant and inexpensive element with the unique characteristic of moderating neutrons without absorbing them. However, its moderating power is limited, requiring the use of large quantities to achieve the desired effect.

In nuclear reactors, graphite can be used as a moderator. However, it poses a potential safety risk because it can burn in the presence of air and produce radioactive gases.

This risk was tragically realized during the Chernobyl nuclear power plant accident in 1986. The accident was triggered by a combination of design flaws and poor operating procedures that led to reactor overheating. At excessive temperatures, the nuclear fuel melted, and the graphite moderator caught fire, causing an explosion and releasing massive amounts of radioactive material into the environment.

This is indeed what happened during the accident at the Chernobyl nuclear power plant in 1986.

The Chernobyl accident was triggered by a series of design errors and poor operating procedures that led to an overheating of the reactor. When the reactor reached excessive temperatures, the nuclear fuel melted and the graphite of the moderator caught fire, causing an explosion and releasing massive amounts of radioactive material into the environment.

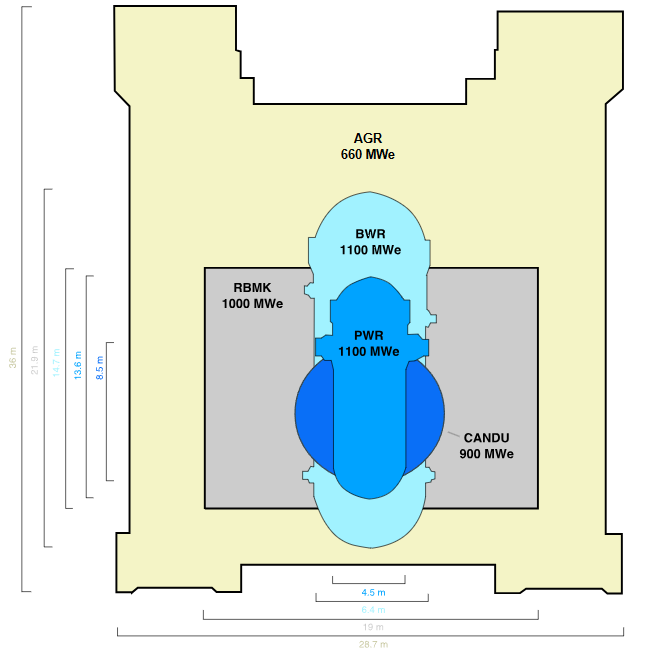

This figure compares the sizes of various reactors: an AGR of 660 MW (in beige), an RBMK of 1 GW (in gray), a PWR and a BWR of 1.1 GW each (in light blue and blue, respectively), and a CANDU of 900 MW (in dark blue). It clearly illustrates the impact of the type of moderator used on the size of the reactors.

The maximum height is 36 meters, and the width is 28.7 meters.

Summary

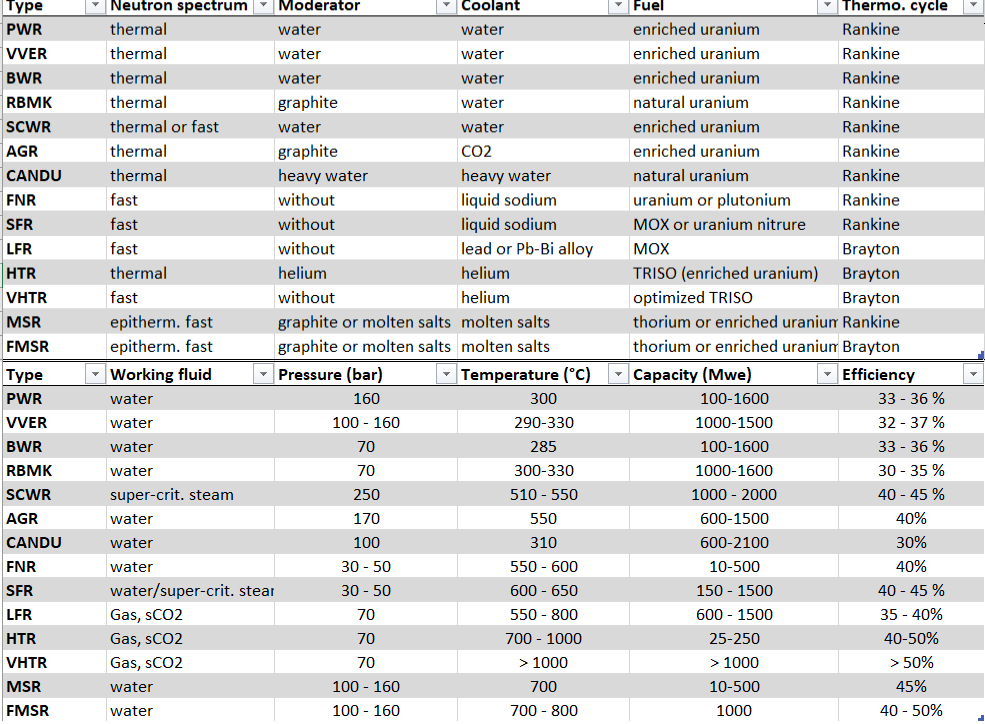

This table summarizes the main characteristics of the nuclear reactors that have just been presented.

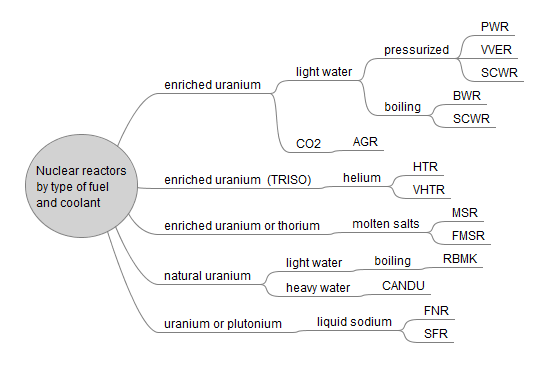

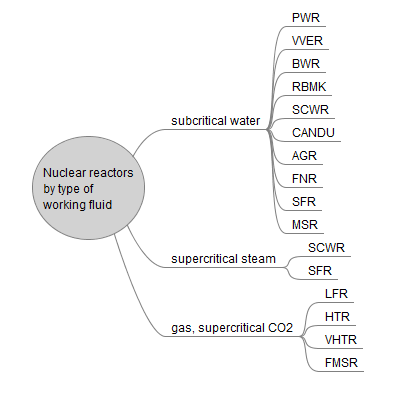

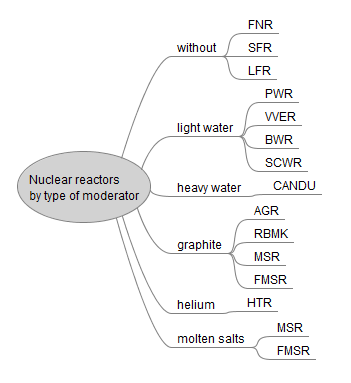

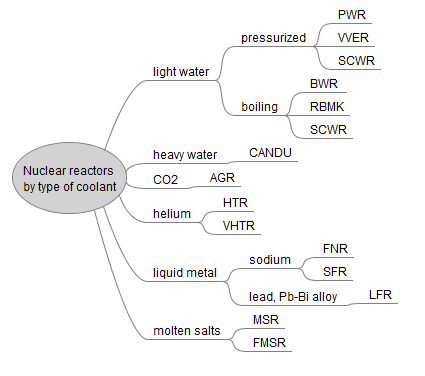

Mind Maps

These four mind maps present the different types of existing reactors in graphical form, categorized by moderator, coolant, fuel, and thermodynamic fluid.

These graphical representations help visualize the complex relationships and distinctions between various reactor types based on their key characteristics.

|

|